Food & Feeds

Extrusion Technologies for the creation of Food and Feed Products

In the past few years, there has been an increase in the production of rice in Guyana. This product is consumed mainly in its natural state but also gives by- products, such as bran and broken rice, which is commonly used for animal feed.

IAST, through funding from the Government of Guyana has developed several products to convert this raw material into other value-added commodities. This is done via extrusion, hence increasing the economic value of the primary agricultural commodity Rice.

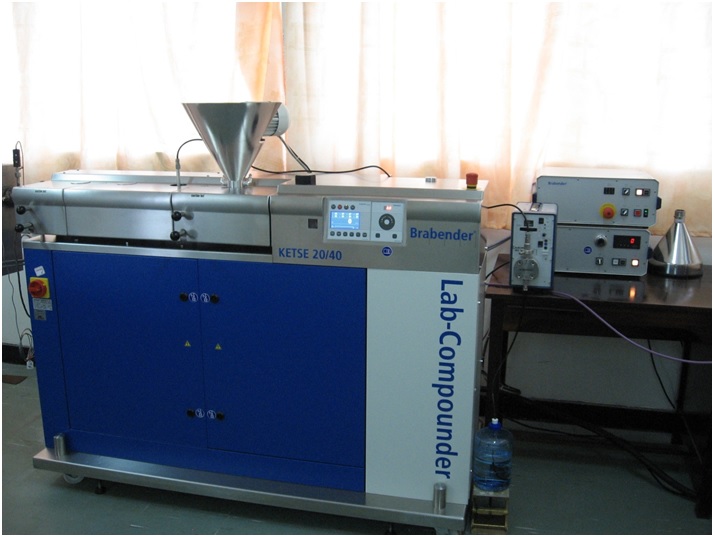

The Department currently utilizes a KETSE 20/40 Lab Compounder which is a state of the art multifunction co-rotating twin screw Extruder. It features:

- A Clamp barrel

- Variable processing time

- Interchangeable screw element

- Electrical heating / water cooling

- Processing temperature up to 400 0C

- Vertical screw feeder

This scaled-down machine in combination with its comprehensive adaptability and easy handling system is an excellent laboratory apparatus for the development of the Department’s projects.

The projects developed relate to the extrusion of broken rice from the rice milling industries to produce a variety of products:

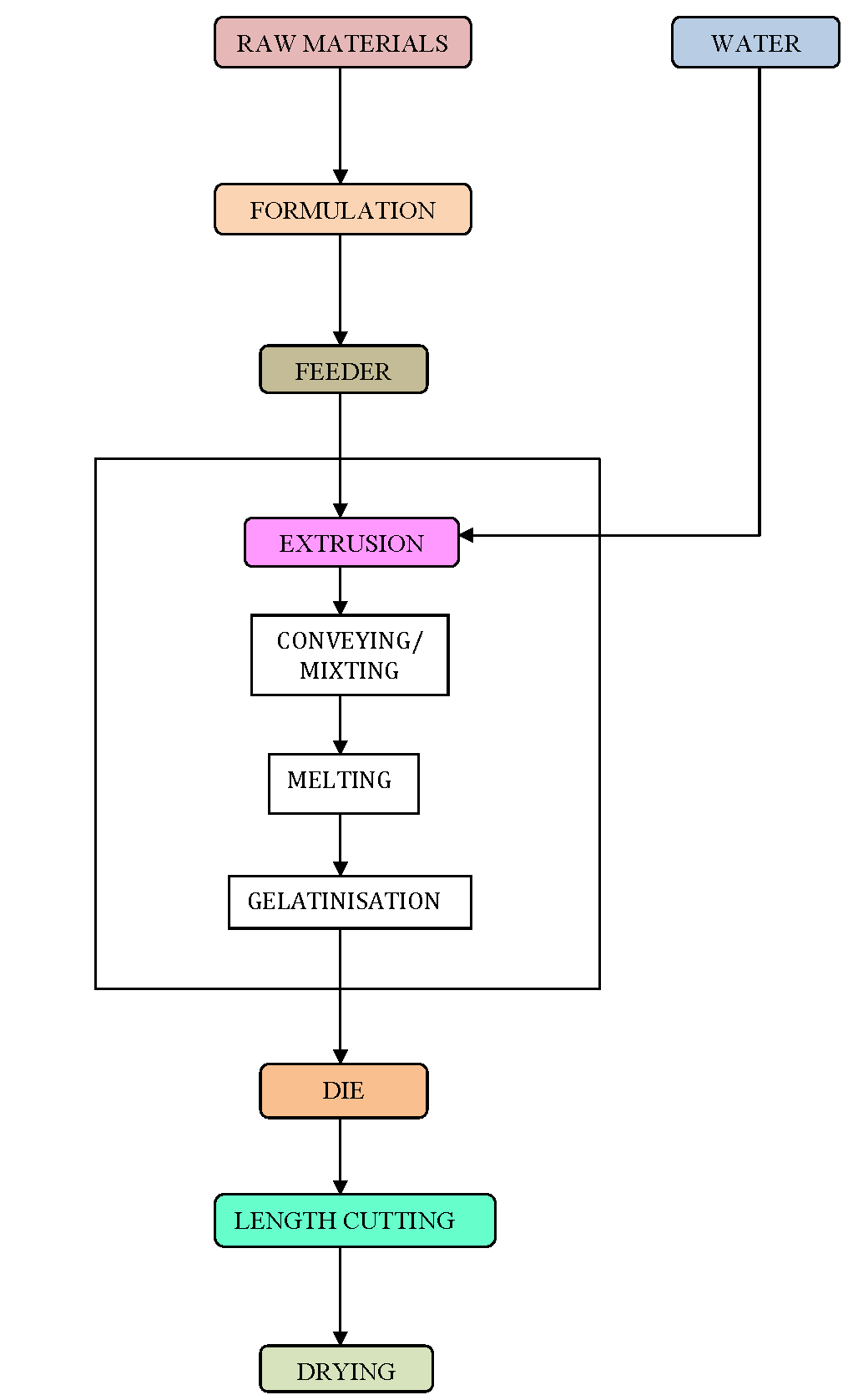

Extrusion Process

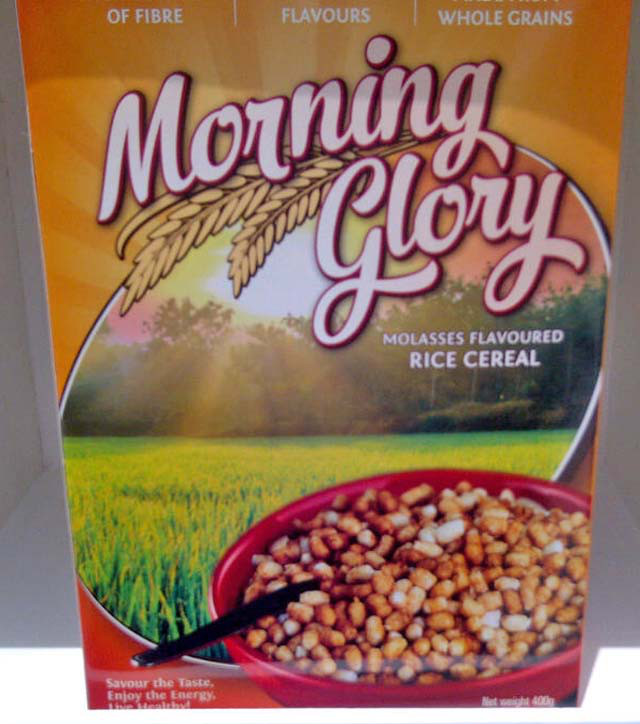

Rice Cereal Project

The Institute has developed a variety of rice-based cereal products, flavored with Molasses and Chocolate. These products are produced through the extrusion cooking of milled rice (rice flour) and other ingredients, including flavor, sugar and a vitamin cocktail, added as a coating post-extrusion. The cereals have a very competitive nutritional profile, and are an extremely high source of fibre due to the inclusion of rice bran in the formulation.

Furthermore, the product is composed of more than 95% locally grown and milled rice and indeed is made from waste broken rice: 30% of all milled rice in Guyana ends up as broken, second grade rice to be utilized as feed. In addition to the cereals, the institute has developed a nutritional bar product, which rivals other Brands such as the popular Nature Valley and Kashi Brands in terms of nutritional profile. This product incorporates approximately 78% of the cereal product, and contains a variety of other local ingredients, including locally grown peanuts.

These products were developed at a laboratory scale and then scaled up to a pilot level at the IAST. Furthermore, the institute developed a branding strategy, business plan and packaging for the product, and designed a full scale (200 kg/h) commercial plant to produce the product.

The Government of Guyana allocated $100, 000, 000 to the project, and the Institute designed and built the factory building for the commercial facility to produce the product, at Anna Regina, Essequibo Coast. The IAST has engaged with the producers of the commercial production line in China, and after travelling to China to inspect the equipment from several producers, the equipment was purchased and is expected to arrive in January 2017.

In the meantime, the IAST has been producing the cereal and nutrition bars at a pilot scale, with the aim of securing markets for the product ahead of the time when the facility would be completed and needs to begin to incur operational expenditure. In addition to a number of interested parties in Jamaica and Trinidad, the IAST has also been participating in a pilot study with the National School Feeding Program designed to test the acceptance of a variety of nutritionally suitable products, by the students themselves. The acceptance level of the students to both the cereal and the bar has been an enthusiastic 100%! Therefore, the program is recommending that the cereal and the nutrition bars be one of the main products utilized by the National School Feeding Program. This will allow the facility to be able to operate one shift and allow the facility to operate at a return on capital investment of approximately 14%. With additional markets being accessed, this ROI will climb as additional shifts are employed (the facility is designed to operate for 24 hours).

Expanded Fish Feed

IAST’ Food and Feed Department, in fulfilling its mandate of producing value added products from mostly locally sourced commodities while promoting extrusion technology and to transfer this technology to an investor, developed an extrusion process using broken rice, soya meal, fish meal and pre-mixed vitamins to produce a fortified well-balanced Expanded Fish Feed.

The composition of the expanded fish feed not only has broken rice, fish meal and soya meal, but also has the necessary vitamins and minerals for optimal density, high yield and fast growth.

Mixed with water and extruded into pellets which are dried, it is then fortified with vitamins and oils. The expanded fish feed can be adjusted to varying farming methods by modifying the speed of the cutter to get the appropriate dimension of feed that is required by the farmer.

The expanded fish feed was found to float better and longer when compared to conventional fish feed. The dry feed pellets are stable for relatively longer periods, for convenient storage and distribution. In addition, the farmer may be required to use less feed when using the expanded fish feed.

Risotto Rice, Thai and Vermicelli Noodles

Risotto Rice

IAST’s Food and Feed Department, in fulfilling its mandate of producing value added products from locally sourced commodities while promoting extrusion technology and to transfer this technology to an investor, developed an extrusion process using locally grown rice as a main ingredient to produce Risotto Rice, Thai and Vermicelli Noodles.

Thai Noodles

The Institute’s process of extrusion created noodles which are more delicate in texture and flavor than wheat-based noodles such as pasta. The rice derived products are naturally low in gluton content.

Vermicelli Noodles

As a product made of 100% white rice, the noodles and risotto are naturally gluten-free, making them a great choice for those suffering from celiac disease– the inability to digest gluten or have a gluten sensitivity.

Pakaraima Flavours – Sun Dried Tomato Salad Dressing

The IAST, working in collaboration with the Ministries of Indigenous Peoples Affairs and Social Cohesion, has embarked on a project centered on the village of Paramakatoi and surrounding communities of Bamboo Creek and Mountain Foot, located deep in the Pakaraima Highlands, in Region 8 (Potaro-Siparuni Administrative Region). This project also falls within the ambit and deliverables of the Hinterland Employment and Youth Service (HEYS), a youth program being implemented by the Ministry of Indigenous Peoples’ Affairs. The project is a vertically integrated value-added agri-food project, centered on the production of Organic Sundried Tomatoes and Salad Dressings.

Every family in the three communities cultivate a small farm, on a subsistence level.

The residents of Paramakatoi and surrounding communities practice organic, sustainable agriculture on the slopes and valleys of this mountainous region. No fertilizer or pesticides are used, and the locations of the farms are shifted regularly, resulting in natural reforestation. The conducive climate and rich soil, coupled with the rotation of farm locations results in remarkable yields of agricultural produce; far outstripping yields in other parts of the country. However, the lack of a local market, and the astronomical cost of air transportation to populated markets are barriers to the development of agriculture as an income generator.

The lack of access to power and the high cost of fuel has stymied the development of post-harvest processing industries for preservation of agricultural produce, which may have allowed the difficult but passable road system to be used to access markets.

Given these conditions, the use of solar and biomass drying as a means of preservation presents a proven and appropriate technology (the Institute of Applied Science and Technology has developed an effective hybrid solar/biomass dryer and successfully tested it on the coast on a variety of fruits and vegetables, and this technology is used effectively in many rural regions of the world). Given the organic farming practiced, the potential for production of organic dried preserved fruits, vegetables, spices and flavor herbs and essential oils in the region is high. Furthermore, the remote location, Indigenous Lifestyles and pristine environment of the Pakaraimas provide additional branding appeal to discerning customers, particularly in North America and Europe, but also in the Caribbean, especially at tourist resorts catering to European and North American tourists. Dehydration, whilst an effective means of preservation, can also be used as a means of developing flavor, and of course for many fruits and vegetables, significantly reduces the weight to be transported.

This project has the potential of transforming the communities in Paramakatoi, Mountain Foot and Bamboo Creek, through generation of income via a vertically integrated Organic Agri-Food Business. Importantly, there would be no “middle-men” and the village shall own the rights to the brand, the formulation, and the entire business. Therefore, all proceeds shall redound to the benefit of the community. Beyond these communities, however, will be the development of a national facility where Indigenous Youth can learn about Agri-Business, Post-Harvest and Solar Processing, and Value-Added foods. The multiplier effect, through the training to be conducted by the IAST, but also through the example of the successful injection of technology for community enterprise and development would be of immense value to the national development of our Indigenous Communities. The benefits of this one project being successful are immense because it would demonstrate what can be accomplished.

The Institute is currently supervising the construction of the Solar Drying and Processing Facility in Paramakatoi.

INSTITUTE OF APPLIED SCIENCE AND TECHNOLOGY

UNIVERSITY OF GUYANA CAMPUS,

TURKEYEN, GREATER GEORGETOWN,

GUYANA

TELEPHONE: (592) 222-4212-5, (592)-222-4218, (592)-222-5864

FAX: (592) 222-4229

For further information kindly contact:

Mr. DEONARINE JAGDEO

Director (ag.)

RAYANN HINCKSON

Confidential Secretary

r.hinckson@iast.gov.gy